Overview

The Phoenix series is designed to offer the flexibility required for Q.A, R&D, and engineering process development

The Phoenix 10 series has a special designed optical system for reducing the light scattering and able to upgrade to a higher model with ease. The fluid is dispensed from the manually controlled syringe system. The position of the sample stage precisely adjusted along X-, Y- or Z-axis for the fine image analysis.

Features

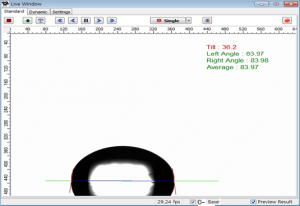

- Data checking instantly without open analysis window by preview results

- Data comparison function

- Improved precision and reproducibility by the elimination of operator error

- Available to connect to Laptop or Desktop PC via USB port

- Auto calculation of surface energy and work of adhesion

- High-resolution and powerful image capture system,

- Automatic & manual image analysis

Capabilities

- Data checking instantly without open analysis window by preview results

- Static contact angles

- Sequence image captures by time basis & dynamic movies.

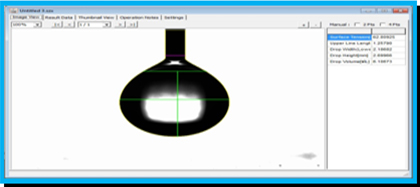

- Surface energy/surface tension by pendant drop method

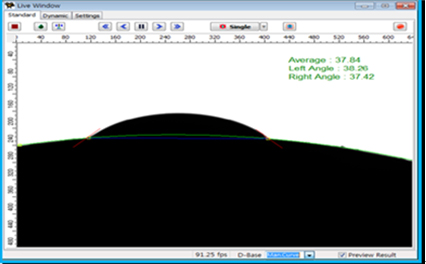

- Real-time contact angle display

- Precise calculation of drop volume

- Data comparison functions

Typical Application

- Semiconductor applications

- Detection of organic contamination on PCB and electronic components

- Evaluation of cleanliness / treatment / coating processing

- Hydrophobicity and hydrophilicity of solid surfaces

- Biological application such as the detection and characterization of proteins

- Adsorption / Wettability of powder and pharmaceutical products

- Analysis of plasma treatment to increase the wettability of polymers surfaces

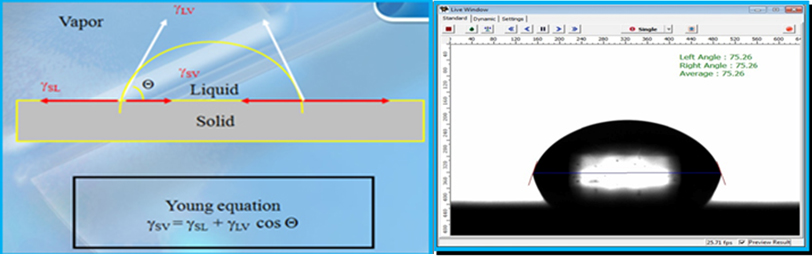

1.Static Contact angle measurement

Measurement range : 0~180°

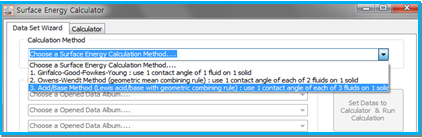

2. Easy Surface Energy calculator (GGFY, Owens Wendt, Lewis method)

Using measured contact angle data itself

3. Surface tension by pendent drop method

(1mN/m ~ 1000nM/m)

4. Curved surface sample measuring function

Software function

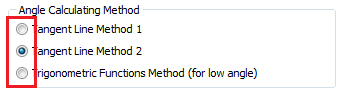

1. Static contact angle calculation by three modes

- Tangent line method 1(For Tilting contact angle and bigger drop volume)

- Tangent line method 2(For common measurement)

- Trigonometric function (For low angle measurement : less than 30degree)

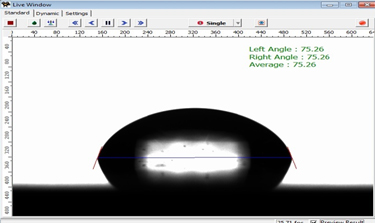

2. Realtime Preview Result before capture function

- Able to check condition of image before capture - Measurement data will be display before capture

- Able to check an instant contact angle and surface tension data

3. Manual mode for critical sample

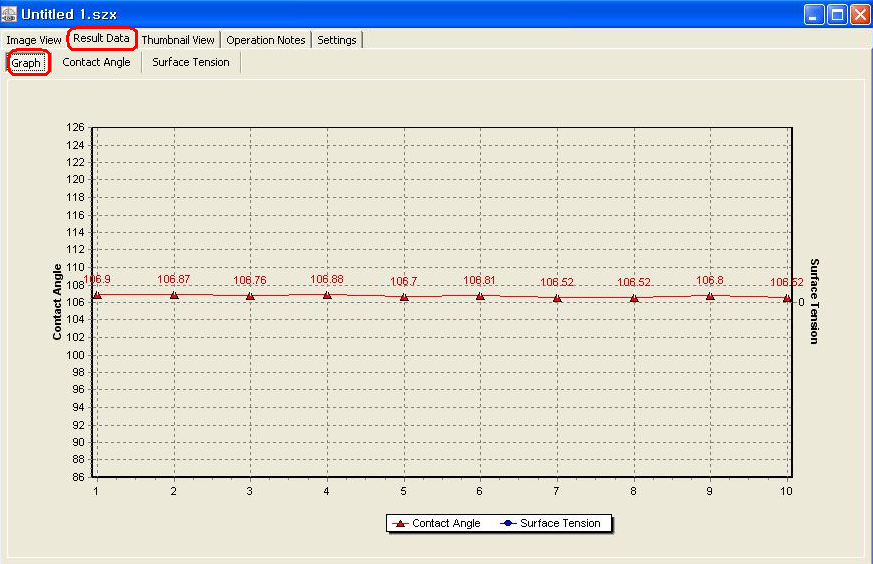

4. Auto calculate average

- Automatic calculation of the average contact angle data by the software based on the frames captured.

5. Graphical data

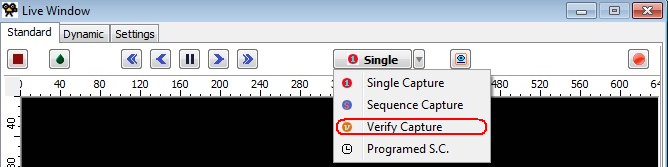

6. Four types of capture modes

6. Four types of capture modes

- Single mode - One by one capture image

- Sequence mode - Able to check by interval time base

- Verify mode - Will show only one Maximum frequent image

- Programmed mode - Use it with Tilting, Time base by triggering

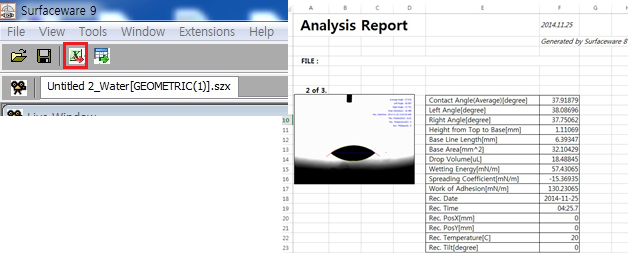

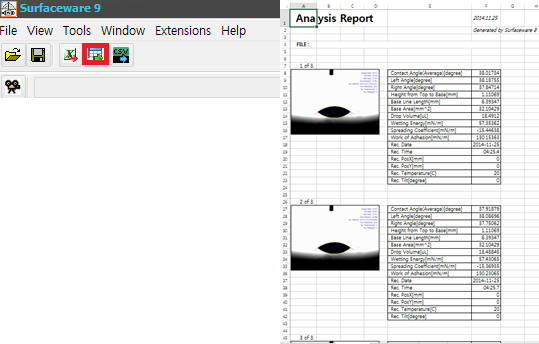

7. Export captured date to Excel (2 modes)

- Selected only one image export on whole measured image

- All images export at once into an collection

8. Manual define Base line function

- User can define the baseline manually for difficult to calculate contact angle

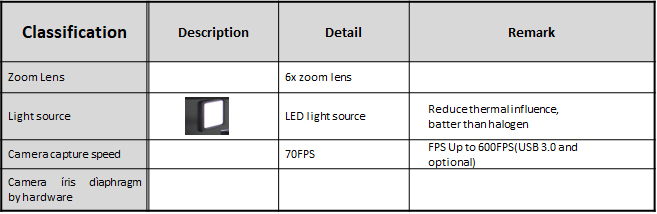

Hardware Features:

Data Analysis Specification

| Method | Accuracy | Software resolution | Range | Data information | extension | |

| Static contact angle | Tangent line metnod1 | ±0.1degree | ±0.01degree | 0~180° | Average contact angle, left contact angle, right contact angle, drop volume, height, base line length, base area, measured time, wetting energy, spreading coefficient, work of adhesion | |

| Tangent line metnod2 | ||||||

| Trigonometric function | ||||||

| Surface tension | Pendent drop method | ±0.1mN/m | ±0.01mN/m | 1~1000

mN/m |

Drop volume, Surface tension | |

| Surface free energy | G.G.F.Y | ±0.1mN/m | ±0.01mN/m | Surface free Energy | ||

| Owens-Wendt | ±0.1mN/m | ±0.01mN/m | Surface free Energy, Dispersive value and Polar value | |||

| Lewis (Acid/Base) | ±0.1mN/m | ±0.01mN/m | Surface free Energy, Dispersive, Polar, Acid, base value | |||

| Capture speed | CCD | 0~70FPS | 0~315FPS (Optional) | |||

| Machine vision Resolution | 640x480 | 1280x1024 (Optional) | ||||

| Sample stage | X axis sliding | |||||

| Data export method | Two modes of Excel export, BMP, CSV file | |||||

| Data save method | Save as .SZX

and Excel |

|||||

| Device dimension | W700(mm)xD260(mm)

xH650(mm) |

|||||

| Power | 110/220V(50/60HZ) |