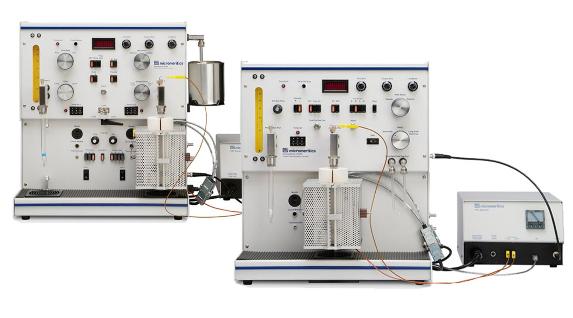

Micromeritics ChemiSorb 2720 / 2750

The ChemiSorb 2720 and ChemiSorb 2750 can be equipped to perform chemical and physical adsorption tests that are central to the development, testing, and production of catalysts. They employ the dynamic (flowing gas) technique of analysis by which the quantity of gas taken up by the sample or released from the sample surface is monitored by a Thermal Conductivity Detector (TCD). Data obtained by the instruments can be used to calculate key parameters for catalyst characterization: metal dispersion, active surface area, BET surface area, average crystallite size, surface acidity or basicity, and activation energy via first order kinetic models.

Features

The ChemiSorb 2720

Versatility in an Inexpensive Chemisorption System

This basic system without the TPx option makes chemisorption and physisorption analyses affordable to even the most modestly funded laboratories. The instrument rapidly and accurately performs pulse chemisorption studies and surface area analyses. The ChemiSorb 2720 features one port dedicated to performing the sorption analysis and a second port designed for sample preparation. It also features a built-in cooling fan for the sample port, four carrier gas inlets, one prep gas inlet, and the optional capability to accommodate a mass spectrometer or other external detector attached at the exhaust port. In addition to chemisorption experiments that include determining the percent metal dispersion, active metal area, crystallite size, and quantifying acid and base sites, a range of physisorption experiments including BET surface area, Langmuir surface area, and total pore volume can also be conducted. Hands-on calibration and dosing procedures make it an excellent teaching tool for gas-solid surface interaction studies.

The basic instrument (without the ChemiSoft TPx option) provides two ways to collect data: 1) via a front panel meter that may be calibrated to display gas volumes adsorbed onto or desorbed from a sample, and 2) by a chart recorder monitoring the analog output from the thermal conductivity detector.

- Dual ports, one for analysis and one for sample preparation.

- Built-in sample cooling fan, four carrier gas inlets, and one prep gas inlet.

- The basic instrument can measure percent dispersion, active metal area, crystallite size, and quantify acid and base sites using pulse chemisorption. Physisorption tests include BET and Langmuir surface area,and total pore volume.

- An optional access fitting allows the ChemiSorb to utilize a mass spectrometer or other external detector for identification of desorbed species or reaction products.

The ChemiSorb 2750

Higher Precision and Versatility

The ChemiSorb 2750 (built upon the same design elements as the Chemisorb 2720) has been further enhanced with the addition of an injection loop for pulsing active gases on the catalyst and features an enhanced dual-port design that allows in-situ preparation and analysis of two samples. Its dual-function sample ports have the capability to be used as either an analysis port or a degas port, eliminating the need to move the sample. This requires less effort and reduces the chances of contaminating an activated sample from exposure to stray gases.

Performing different types of analyses is also easier. In addition to the four carrier gas inlets and three preparation gas inlets, a dedicated gas inlet for the pulse chemisorption gas has been added. Thus the increased number of ports provides a rapid method for gas change overs without the need to manually disconnect, reconnect, and purge gas lines; this further minimizes the risk of contamination and improves the ease of operation.

Higher precision, repeatability, and reproducibility are provided by the incorporation of an injector loop valve in addition to the injection septum. The loops are easily exchanged to provide different injection volumes. Electrically activated inlet valves allow the use of gases containing H2, CO,O2, N2O, NH3, liquid vapor sources, or other adsorptives. Three built-in prep gas inlets and four carrier gas inlets allow for a variety of experiments without having to disconnect, reconnect, and purge gas lines.

| ChemiSorb Features | 2720 | 2750 |

| · Analysis Ports | 1 | 2* |

| · Preparation Port | 1 | * |

| · Injection Septum |  |

|

| · Injection Loop |  |

|

| · Sample Reactor | Quartz | Quartz |

| Gas Inlets | ||

| · Carrier | 4 | 4 |

| · Preparation | 1 | 3 |

| · Loop | 1 | |

| Temperature Control | ||

| · Integrated | 2** | 2 |

| · Max Temperature | 400 °C | 400 °C |

| · With TPx Option | 1100 °C | 1100 °C |

| · Fan-assisted Cooling | 1 | 2 |

| Standard Analysis | ||

| · Pulse Chemisorption |  |

|

| · Physisorption |  |

|

| ChemiSoft TPx Analyses | ||

| · TPR |  |

|

| · TPD |  |

|

| · TPO |  |

|

| · Pulse Chemisorption |  |

|

| · Physisorption |  |

|

| · Loop Calibration |  |

|

| ChemiSoft TPx Reports | ||

| · % Metal Dispersion |  |

|

| · Metal Surface Area |  |

|

| · Average · Crystallite Size |  |

|

| · First Order Kinetics |  |

|

| · Single-point Surface Area |  |

|

| · BET Mulitipoint Surface Area |  |

|

| · Langmuir Surface Area |  |

|

| · Total Pore Volume |  |

|

Added Capability - Optional ChemiSoft TPx System

Optional ChemiSoft TPx System (temperature-programmed controller and software) expands the capabilities of the ChemiSorb 2720 and 2750 to include temperature-programmed reactions, data archiving, and advanced data reduction and reporting options

Optional ChemiSoft TPx System (temperature-programmed controller and software) expands the capabilities of the ChemiSorb 2720 and 2750 to include temperature-programmed reactions, data archiving, and advanced data reduction and reporting options- Expanded physisorption capability includes multipoint BET surface area.

ChemiSorb 2720

ChemiSorb 2750