Bettersizer S3 Series

—— State-of-art particle size & shape analysis system

- Particle Sizing

- Particle Shape Analysis

Bettersizer S3 Series

Breakthrough particle sizing solution for industry, research and development laboratories

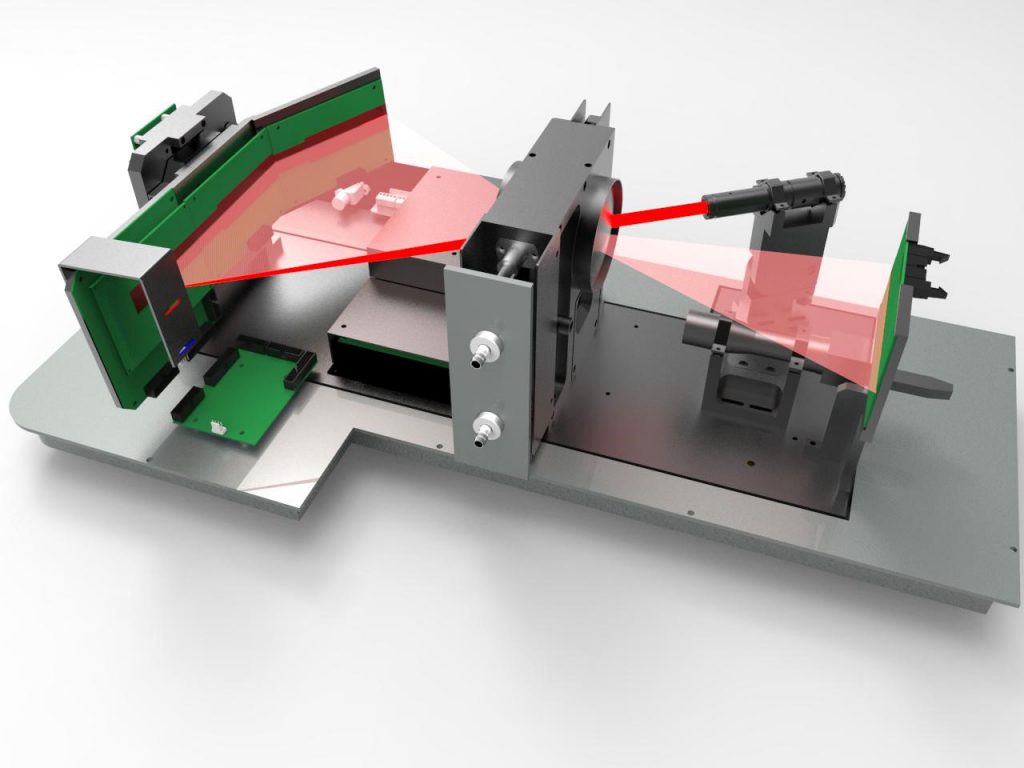

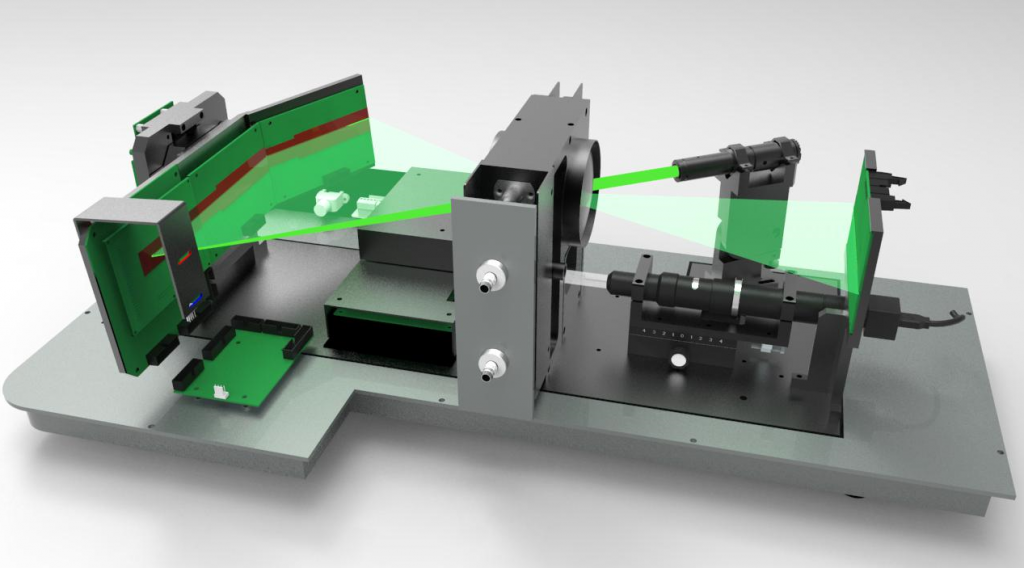

Bettersizer S3 series delivers best-in-class performance through incorporating cutting-edge innovations and functionality into the development of world-class particle analysis system. With a compact yet flexible integrated body, Bettersizer S3 series combines our innovative Dual lenses & oblique incidence optical system (DLOIS) for the wide testing range from 0.01 to 3500 mm, dynamic particle shape analysis for shape results of larger particles, smart operation functions, and software for quick and productive measurement.

These advanced technologies contribute to the unique dynamic analysis of particle size and shape and provide the most accurate, high-resolution, high sensitivity, excellence repeatability, cost-effective, and easy-to-use Bettersizer S3 series you can ever imagine possible.

| Model | Bettersizer S3 | Bettersizer S3 Plus |

| Measuring range | 0.01-3500 mm | 0.01-3500 mm |

| Measuring method | Laser | Laser particle size+

Dynamic particle shape |

| Dispersion system | Wet | Wet |

| Auto Refractive Index measurement | Yes | Yes |

Intelligent Particle Sizing Performance

S3 defines a new era in particle sizing and shape measurement, a culmination of our years of experience excel in particle sizing and shape analysis instrumentation.

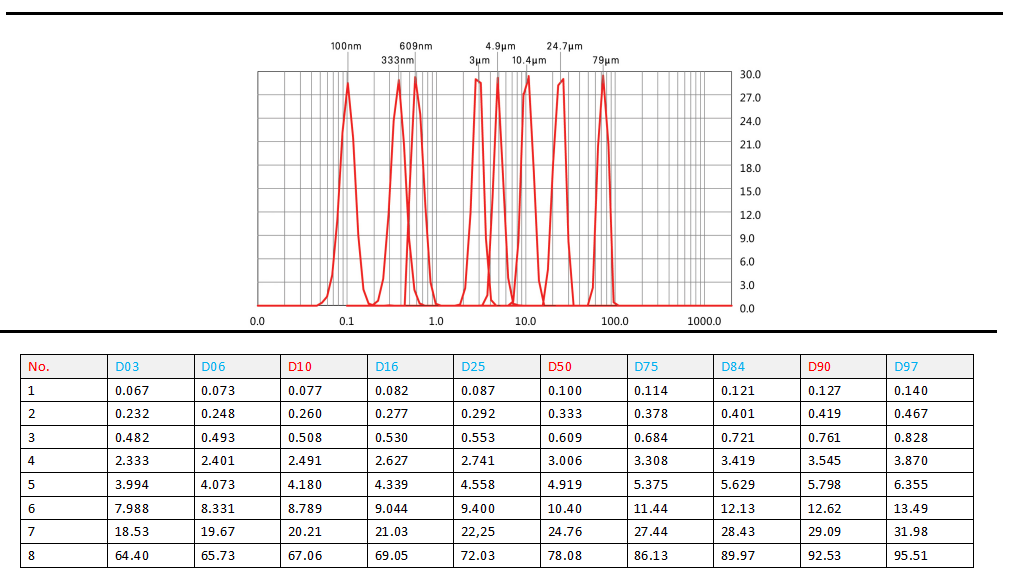

Accuracy

The accuracy of Bettersizer S3 series as verified by measurements of eight standard samples is shown below.

Repeatability

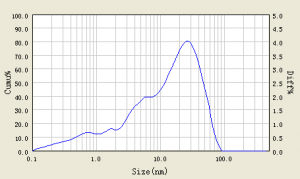

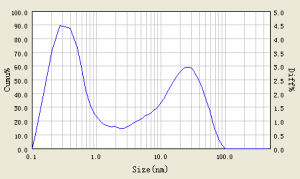

Bettersizer S3 series measures samples with a wide distribution range. Six repeat measurement results under same analysis conditions yield good repeatability as shown in the following graph. Average repeatability deviation of D50 is 0.31%.

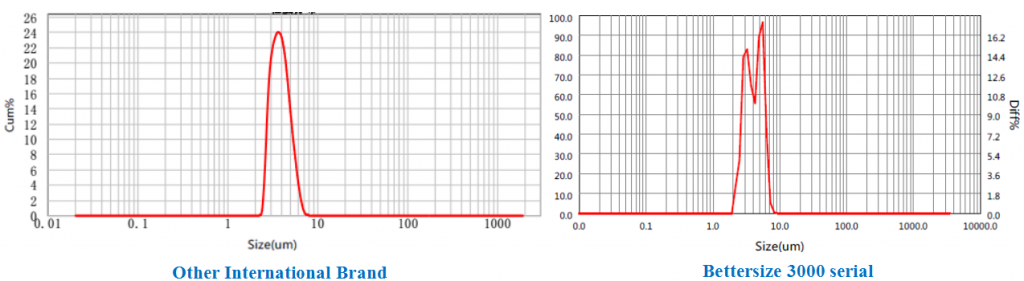

Resolution

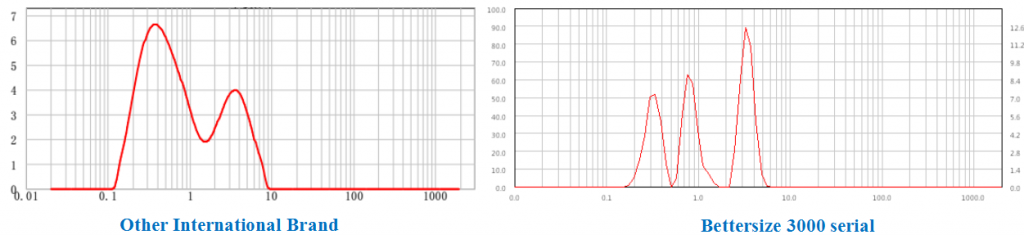

Detection limit test : A mixture reference standard samples of 3.1 µm and 5.1 µm nominal diameter was used to gauge the resolution of the Bettersizer S3 against the industry benchmark particle sizing instrument. The mixing ratio of 1.65 was used for the test. Bettersizer S3 series clearly out-resolve the benchmark instrument as shown in the following graphs.

Sensitivity

Test methodology: Measurement with a mix reference standard sample of 0.3mm, 0.85mm, and 3.5mm was performed against a benchmark instrument. Bettersizer S3 series resolves three peaks in the measurement result, while the benchmark instrument only able to resolve two peaks.

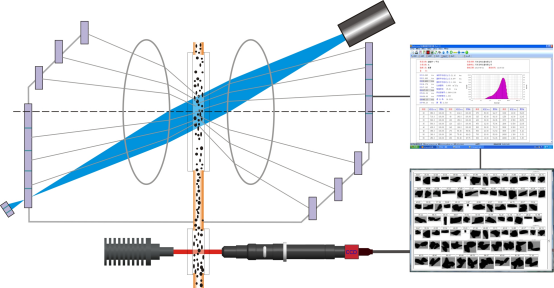

- Dual lenses & oblique incidence optical system (DLOIS)

Provide wide measuring range from 10 nm to 3500 μm

Innovation of Fourier optical system

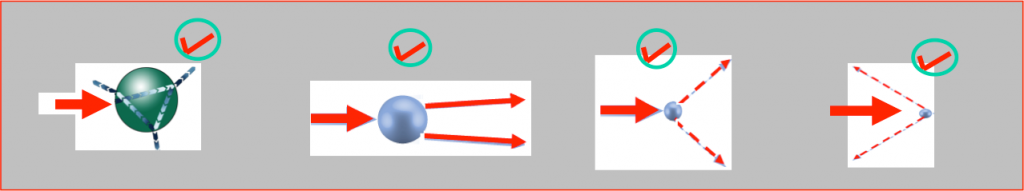

DLOIS of Bettersize is a novel technology based on Fourier optical system. By an addition of the second lens at the symmetric path behind the sample cell, DLOIS can detect backward scattered laser light. The second lens also functions as a collimating lens which turns the diverging laser beam into parallel beam before the sample cell. The parallel beam impeding on the sample cell have the advantage of large and constant intensity circle of illumination of the samples inside the cell. In a laser diffraction measurement, the forward and backward diffraction lasers are generated by a single laser source will have a consistent wavelength, datum, and continuity.

Wide measuring range

The revolutionary DLOIS in Bettersizer S3 series changes the position of the laser beam from the conventional parallel optic to the oblique angle optic. The oblique angle beam widens the scattering angle of the laser beam, providing a wider measuring range from 10 nm to 3500 μm and broaden detection angle up to 165 degrees. This advantage when used in the computation of the particle size with the Mie theory, produce an impressive precision and accuracy results.

The features of DLOIS:

- The back- positioned lens is both the laser beam collimating lens and the backward scattering laser detection lens.

- Oblique incidence optics achieves the detecting angle of 0.02-165 degree and the measuring range of 0.01-3500 μm.

- 90 surrounded detectors on the dual-lens focal plane improve the resolution ratio and measuring accuracy.

Auto material Refractive Index measurement

Auto material Refractive Index measurement

A solution to measure the unknown Refractive Index & verify the known ones. A powerful solution especially for researchers working on the synthesis of novelty materials without any prior literature of Refractive Index available.

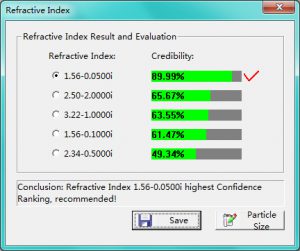

Refractive Index

Mie theory uses Refractive Index at a specific light wavelength of a material as one of the key parameters to calculate particle size distribution. The lack of reliable Refractive Index for a particular powder material would result in measurement without confidence.

Testing result with Correct Refractive Index

Testing result with Wrong Refractive Index

Bettersizer S3 series laser particle size analysis system provides auto material Refractive Index measurement in real time for materials with unknown Refractive Index. It provides a solution for statistically reliable, high confidence data that guarantees the accuracy of particle size analysis results. With the incorporation of auto Refractive Index measurement, Bettersizer S3 series produces the results with high precisions and low variations.

| Material | Refractive Index (reference) | Refractive Index (measured) | Material | Refractive Index (reference) | Refractive Index (measured) |

| Calcium carbonate | (1.53-1.65)-i0.1 | 1.62-i0.1 | Manganese oxide | 2.46 | 2.42-i0.5 |

| Barite | 1.645-i0.1 | 1.68-i0.1 | Aluminum powder | 1.4-i3.9 | 1.42-i3 |

| Carborundum | 2.61-i0.1 | 2.74-i0.1 | Terbia | none | 2.1-i0.5 |

| Zinc Oxide | 2.008-i0.1 | 2.02-i0.1 | Lithium ironpgosphate | none | 1.9-i0.5 |

| Silicate glass | 1.89 | 1.94-i0.001 | Resin material | none | 1.86-i0.01 |

| Carbon black | 1.88-i0.55 | 2.0-i1.0 | Sediment | none | 1.58-i0.1 |

| Hematite | 2.94 | 2.96-i0.5 | Powder coating | none | 3.5-i1 |

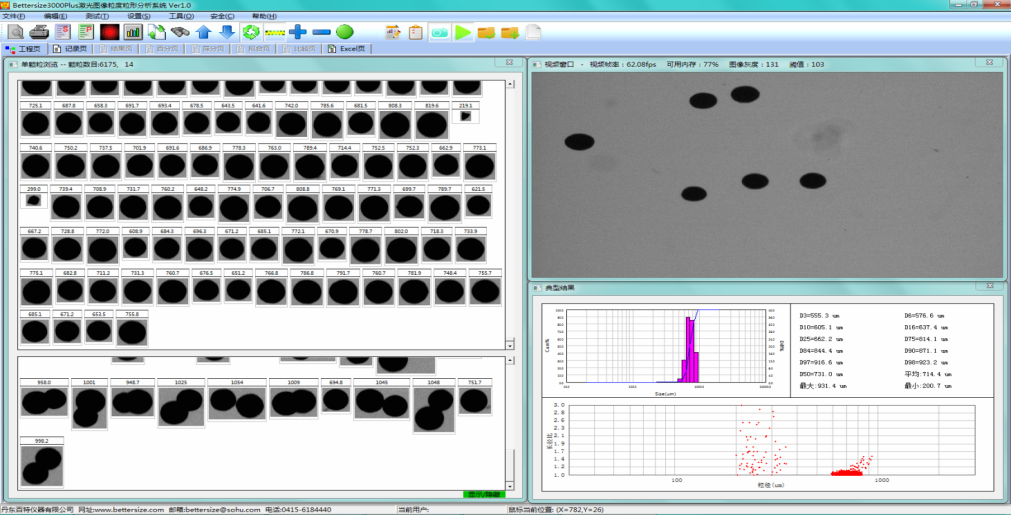

Laser Diffraction + Image analysis

A single solution for both particle size and shape analysis

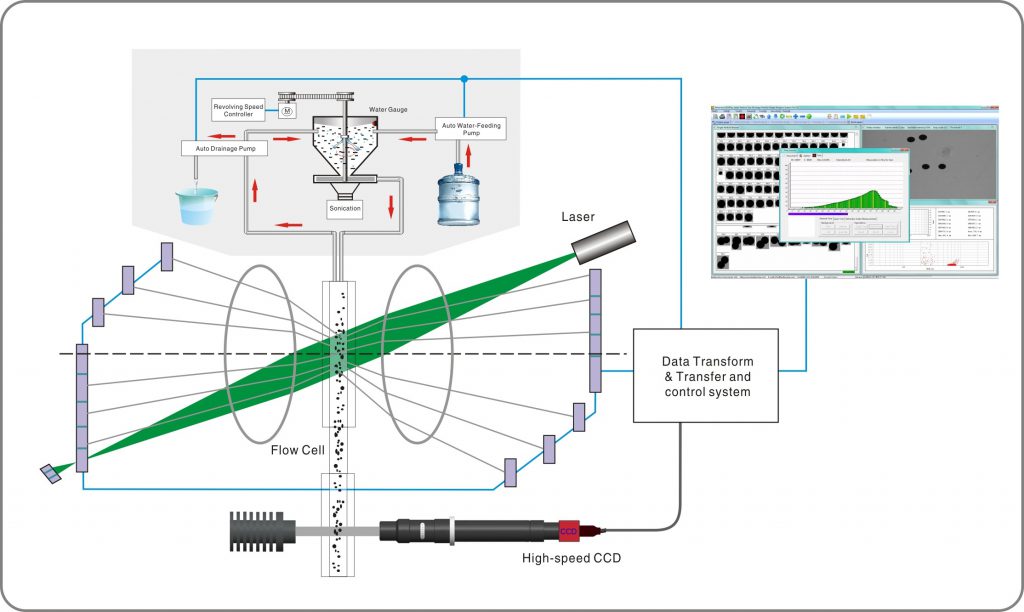

Bettersizer S3 Plus is an upgraded model of Bettersizer S3 with an addition of a microscopic particle shape analysis system. The S3 Plus model contains two testing windows working in series under the same set of circulation and dispersion system. The particle size distribution and particle shape could be analyzed simultaneously with the option to perform individual analysis independently. The two function work in tandem, cross-referencing the particle size analysis results with the shape imaging analysis results for the coarse particle, enhancing a better understanding of the particles as well as improving the accuracy and confidence in the results.

The features of laser diffraction size analysis + image analysis:

- High precision telecentric lens, high-speed CCD camera, high definition imaging without tailing effects.

- Advanced edge recognition + multithreading software technology, high-speed image processing of 10000 particles per minute, able to capture and process data concurrently.

- Accurate fine particles measurement by laser diffraction method, compliments by high fidelity microscopic imaging method for coarse particles, offers an unprecedented advantage for characterization of particles.

- Particle shape analysis including L/D, circularity, acutance, ratio of thickness and radius

Designated Functions

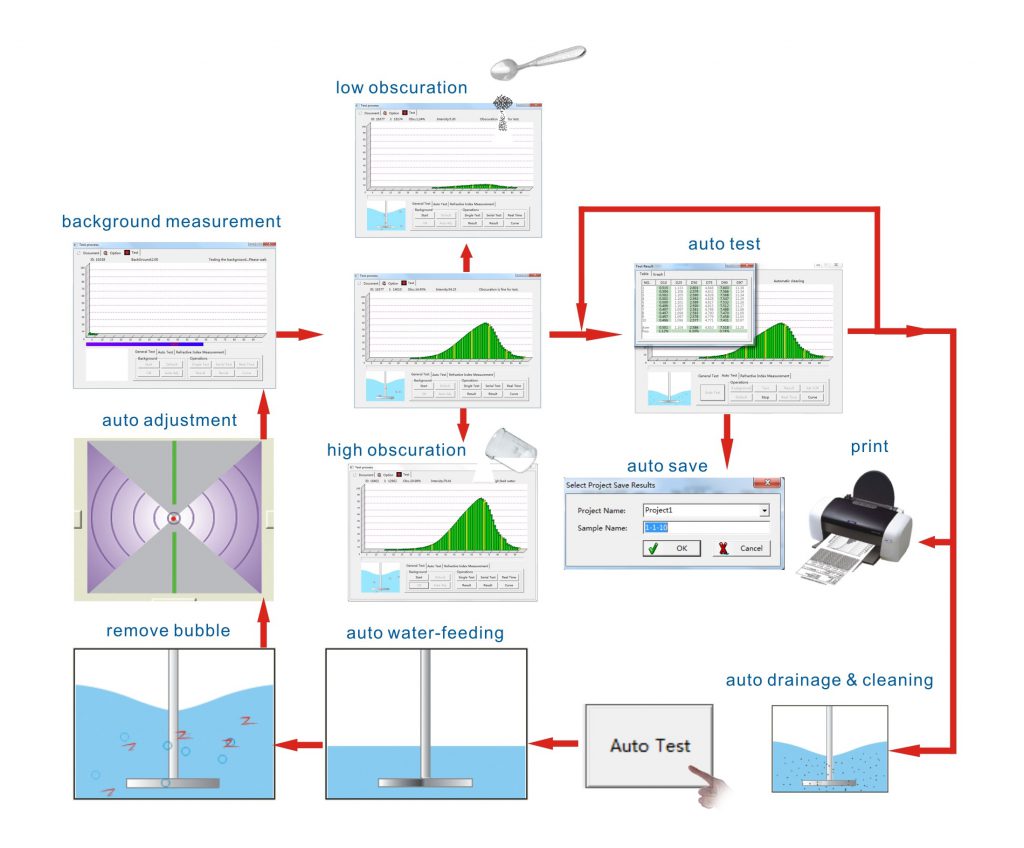

Bettersizer S3 series incorporated multiple functions to help measurement easy, quick and productive.

Standard Operation Procedure (SOP)

The analysis is just by one mouse click

SOP of Bettersizer S3 series provides an intuitive solution for standardized and automatic testing. Click once on the auto test button, the testing procedure will run by itself, including water intake, bubble removal, background and obscuration measurement, testing, rinsing, and result save and print. Just add sample and the automatic analysis procedure is just one mouse click away.

SOP not only provides a simplified procedure but also avoids human operation error; therefore, SOP ensures the repeatability and accuracy of testing results.

Auto circulation & dispersion system

Revealing the true form of every particle through the laser and camera system

The circulation & dispersion system of Bettersizer S3 series consists of the centrifugal circulation pump, dry burning-protect ultrasonic disperser, stirrer, electronic liquid level sensor, auto water feeding / draining / overflow protection system, fogging alarm for sample cell, plumbing, and controller. The hardware system and controlling software ensure a complete sample dispersion hence making sure that each particle would be accounted for through the laser and camera system.

The advantages of auto circulation & dispersion system:

- Upgradeable to solvent circulation & dispersion system for the special sample.

- Adjustable stirring speed coupled with a powerful pump will prevent the large/dense particle from sedimentation inside the circulation vessel.

- Intelligent dry burning-protect dry run protection ultrasound disperser protects the disperser from heat damage when operating the disperser with without water.

- Adjustable ultrasonic power gives users the control over best dispersion for all types of particles.

Auto centering function

Guarantee the perfect condition of optical system

The diameter of laser detector center point is only 100 microns. When processing the analysis, the laser detector center point must coincide with the focus point of the back lens; otherwise, measuring error will occur. The auto centering function of Bettersizer S3 series alleviates the alignment problem altogether. Automatically moves the laser detector center point to the focus point of the back lens before each test, centering function guarantees the perfect condition of the optical system; therefore, provides accurate and repeatable testing results.

Accuracy calibration

Maintain accurate datum lifetime

Bettersizer S3 series features an accuracy calibration function allowing aged or repaired instrument quickly conform to datum status by analyzing the standard sample. This function ensures the operating parameters are maintained at consistent conditions, producing consistent and reproducible measurement across the board for all old and new instruments alike

Reliable Ultrasonic disperser with dry run protection function

Ultrasonic disperser will be damage if water runs out during operation.

Bettersizer S3 series improves its ultrasonic disperser by detecting a dry burning situation and invoke the protection mode. This will safeguard it from damage due to unintentional operating errors.

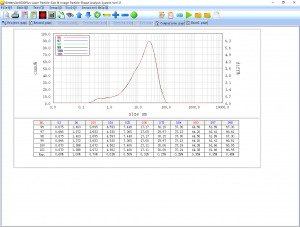

Software: User-friendly interface & powerful functions

Bettersizer S3 series adopts an easy to operate and intuitive software interface. It utilizes the full-screen display for all experimental parameters making it a breeze to run an experiment effortlessly and efficiently.

Export results in multiple formats like PDF, txt, jpg, etc. The flexibility eases the effort for reporting, data publication, data sharing and archival.

- Customizable report format: reporting form could be tailored to suit the format according to the user’s preference.

- Luminous flux compensation: this function can compensate the loss of diffraction light due to the reflection by the glass wall in the sample cell. Thus, high accuracy would be achieved.

- Large particle recognition: instrument will accurately identify any large particle by their first appearance at the dete ction window.

- Real-time repeatability monitor: Allow users to gauge the repeatability of their measurement in real-time .

- Merge calculation: average result for one sample can be calculated by merging of repeatedly-tested results.

- Re-analysis window: data can be re-processed when parameters are changed or modified so that re-acquisition is not necessary.

- Full screen visualized interface: the main interface is result orientated. Acquired data and spectra can be viewed and processed simultaneously.

- Certification: 21CFR PART 11, CE. Bettersizer S3 series is compliance to international standard, and are conforming to pharmacopeia, food, and other industry’s specific requirements.

- Operation video has been added to the software, which guides the user through a step-by-step measurement procedure.

Example Report

Specification

| Testing parameter | Material | |

| Particle size distribution | Suspension, emulsion, dry powder | |

| General | Bettersize3000 | Bettersize3000plus |

| Theory | Laser diffraction | Laser diffraction +dynamic image |

| Analysis theory | Mie and Fraunhofer | |

| Testing speed | 3kHz | |

| Typical measurement time | <10 second | |

| optics | ||

| Green light | Max. 5mW, DPSSL pumping, 532nm | |

| White light | None | Parallel homogenized light source, Image light |

| Lens arrangement | Dual lenses on the right and left of sample cell,oblique incidence | Dual lenses on the right and left of sample cell,oblique incidence |

| Lens design | F-Theta Lenses | F-Theta Lenses,telecentric lens, 0.5X |

| Effective focal length | 223mm | 223mm,image focal length 110mm |

| Detector | ||

| Arrangement | Log-spaced array | |

| Quantity | 96 pieces (forward, sideway, backward) | |

| Angular detection range | 0.02 - 165 degree | |

| Light path adjustment | Intelligent automatic | |

| Size | ||

| Size range | 0.01 - 3500um | |

| Number of size classes | More than 100 customized grades | |

| Particle shape | None | circularity,L/D,kinds of equivalent particle size |

| Refractive Index | Refractive Index measurement | |

| Accuracy | <0.5% | |

| Repeatability | <0.5% | |

| Reproducibility | < 1% | |

| Resolution ratio | Single peak, double peak, multi-peak | |

| Sample dispersing system | ||

| Wet dispersing system | Standard configuration | |

| Dispersing system | ultrasound 50W, 38 KHz Dry burning-resistant Dry run protection system | |

| Water circulation | Centrifugal pump, 500 -2500 ml/min, auto water intake and rinsing | |

| Water capacity | 600 ml | |

| Dispersing system available | Organic solvent compatible system, low volume system | |

| Software | ||

| 21 CFR Part 11 | Comply | |

| SOP Designer | Available Included | |

| Report | More than 14 formats report | |

| Auto test | Available Included | |

| Data export | EXCEL, PDF,WORD, JPG and etc. | |

| System compliance | ||

| Laser class | Class I laser product | |

| System | ||

| Dimension | 690mm x 300mm x 450mm (L x W x H ) | |

| Weight | 30kg | |

| Computer specification | ||

| Communication port | Minimum requirement – one USB2.0 port | |

| Operation system | Windows XP, Windows 7,8 or 10 | |

| Hardware specification | Intel Core I5, 4GB RAM, 250GB HD, CD-Rom or DVD +/-RW drive, wide screen monitor | |