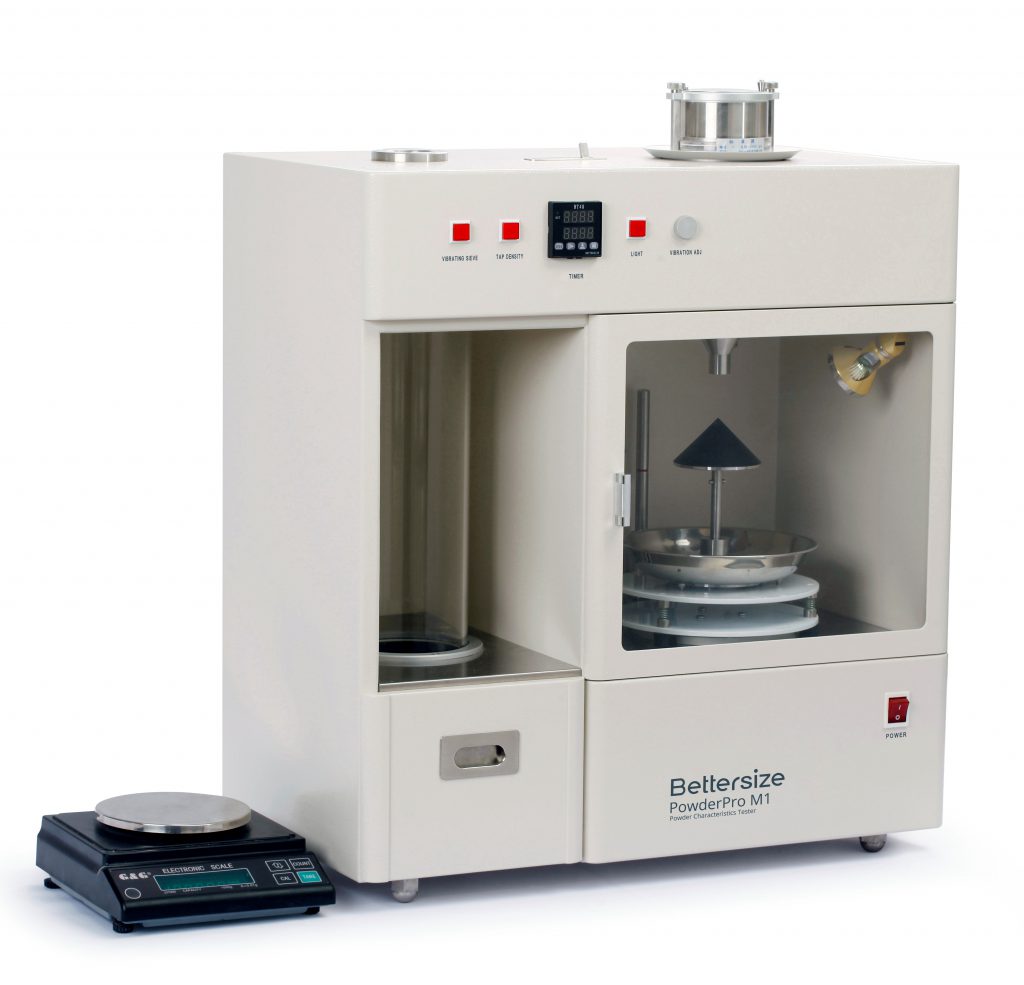

Introduction of PowderPro M1

PowderPro M1 powder integrative characteristic tester is a multifunctional powder characteristic tester. The measuring items of the instrument including tap density, bulk density, angle of repose, flat plate angle, angle of collapse, dispersibility, etc. Calculation items including angle of difference, compressibility, voidage, flowability index, floodabality index, etc. Its characteristics are multiple functions, easy operation, good repeatability, easier for changing measuring condition, complete supporting etc. Its successful development provides a new test method for carrying out powder characteristic test generally. The instrument is mainly used for material scientific research field of powder production enterprises, universities and colleges and scientific research institutions. It will have extensive application prospect for production filed which is related to powder flow characteristic.

Application fields of PowderPro M1

Includes the fields of pharmaceutical, battery material, non-metallic mine, graphite, food, nonferrous metals, powder engineering design, powder property study and teaching, etc.

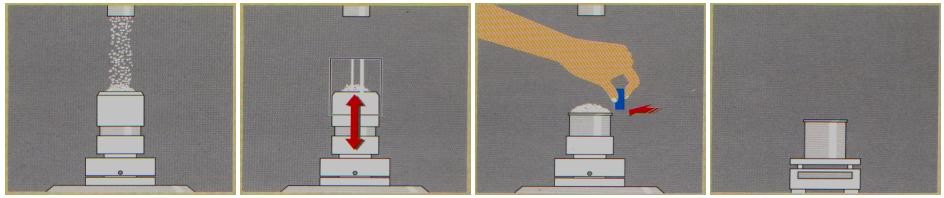

Schematic diagram for test process

(1) Schematic diagram for test process of tap density

(2) Schematic diagram for test process of angle of repose

Reliable performance and easy operation

Reliable performance is achieved thanks to:

-Use of high quality components.

-Use of high quality components.

-Components are inspected and recorded for traceability. A 48-hour failure test before instruments leaves the factory.

-Use of advanced technologies such as dry burning-resistant ultrasonic, auto alignment, dew-point temperature detecting and others

-Comply with CE, FDA 21 CFR Part 11 and ISO 9001-2008 certification.

Test and calculation items and concepts of PowderPro M1

--Angle of repose: In the state of static equilibrium, the acute angle between natural stacking slope and bottom horizontal plane of the powder is called angle of repose. By the way of electromagnetic vibration, it is formed by the powder which freely falling to specific platform. The size of angle of repose directly reflects the flowability of the powder. If angle of repose is smaller, the flowability is better. If angle of repose is bigger, the flowability is worse. Angle of repose is also called rest angle or natural angle of slope.

--Angle of collapse: When measure the angle of repose, stacking powder is impacted by some external forces, and collapse phenomenon may occur on the surface of stacking powder at this time. After collapse, the accurate angle between stacking slope of powder and horizontal plane is called angle of collapse. If the angle of collapse is smaller, the flowability of powder is better.

--Angle of difference: The difference between angle of repose and collapse angle is called angle of difference. If the difference is bigger, the splash property of powder is better.

--Flat plate angle: After lifting up the flat plate which is buried in natural stacking powder vertically, the average value for the angle between free surface (slope) on the plate and horizontal plane and the angle which is after impacting. If the flat plate is smaller, the flowability of the powder is stronger. Generally, flat plate angle is bigger than angle of repose. Flat plate angle is also known as spatula angle.

--Tap density: After filling powder of definite weight (or volume) into specific container, vibrate the container in definite intensity, times and duration, so as to compress the gap between the particles, and particles are in tight state. The powder density at this time is called tap density.

--Bulk density: It refers to the density that powder is filled in specific container and in natural filled state.

--Compressibility: It refers to the ratio of the difference of tap density and bulk density of powder with tap density. If compressibility is smaller, the flowabilty is better. Compressibility is called compression ratio either.

--Dispersibility: After dropping definite powder at definite height, the percentage that the amount drifting outside the collecting tray in total amount of dropping powder is called dispersibility. Dispersibility is degree of drift of powder in the air. It is related to dispersibility, drifting property and splashing property. If dispersibility exceeds 50%, it means that the sample has strong tendency of drift.

--Voidage: It refers to the percentage that the gap of particles in complete powder volume. It will vary as different factors such as particle shape, arrangement structure and particle size, etc. If the particle is sphere, the voidage of powder is around 40%; if the particle is superfine or irregular shape, the voidage of powder is 70-80% or higher.

--Uniformity: It refers to the ratio of D60 and D10 which is calculated by particle size distribution according to sieving method. It is used for coarse powder that has less coherence.

--Cohesion: According to the characteristics of particles in the process of sieving, an explanatory measuring index for the internal tress of particles is called cohesion. If the cohesion is bigger, the flowability of powder is worse. Cohesion applies to fine powder which is easier for agglomeration or micro powder.

--Flowability index: It refers to weighted sum of angle of repose, compressibility, flat plate angle, uniformity and agglutination. Flowability index is related to compressibility.

--Floodability index: It refers to weighted sum of flowability index, collapse angle, difference angle and dispersity.

Specification

| Standard | PowderPro M1 | |

| Chinese standard | GB/T16913-2008 4.5, GB/T1479.1-2011, GB/T5162-2006 | |

| US standard | ASTM D6393-14 | |

| USP | USP32-NF27<616> | |

| EP | EP7.0 07/2010:20934 | |

| Testing Parameter | ||

| Repeatability | ≤5% | |

| Drop height | 3mm or 14mm | |

| Vibration frequency | 50-300 times per minute (continuous adjustment) | |

| Control terminal | Manual operation | |

| System | ||

| Dimension | 580mm x 350mm x 650mm (L x W x H) | |

| Weight | 37kg | |

| Power supply | AC220V, 50/60Hz, 200W | |