Phoenix MT(M.A.T) Brochure

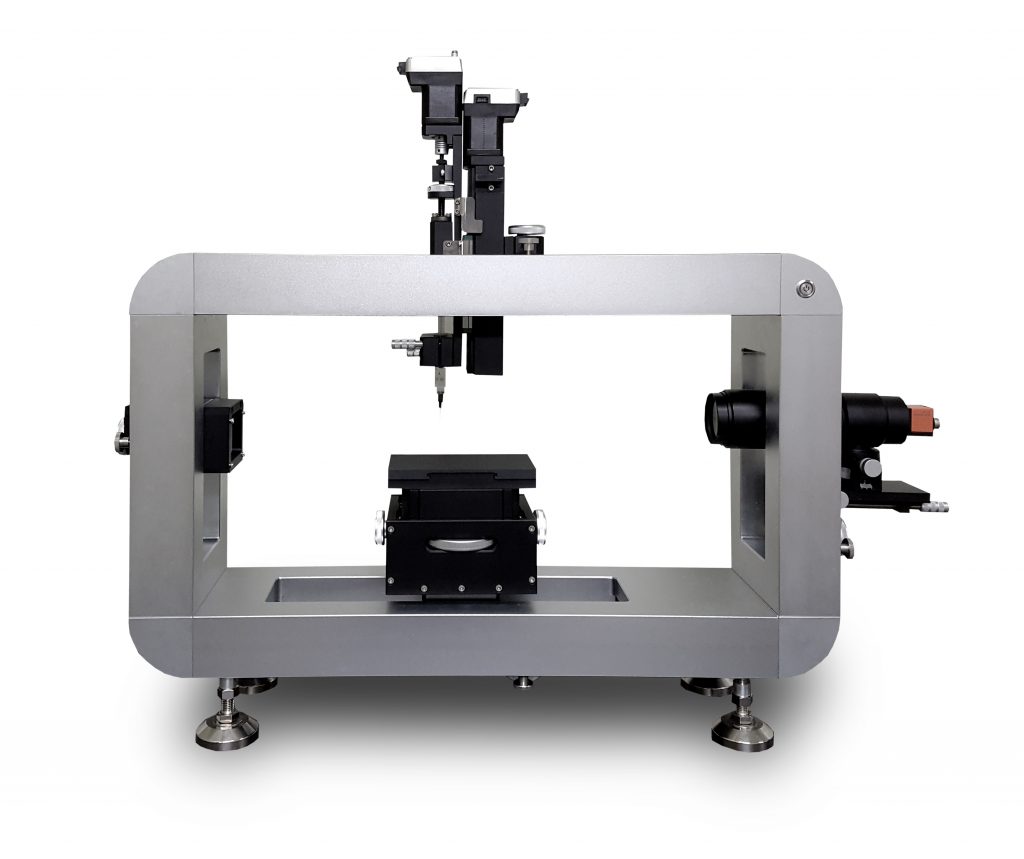

Worlds First: The New Stages That Define Performance!!

A New Level of designing performance and Flexibility

It is the world’s first model that can be used by turning the equipment, the individual modules can be separated, and the length of each main frame can be selected to change the model to suit almost all samples.

Any Sample

By the transform device, able to make suitable condition of hardware easily

Any Application

All modules are placeable for several different sample

New Stage Features 1:

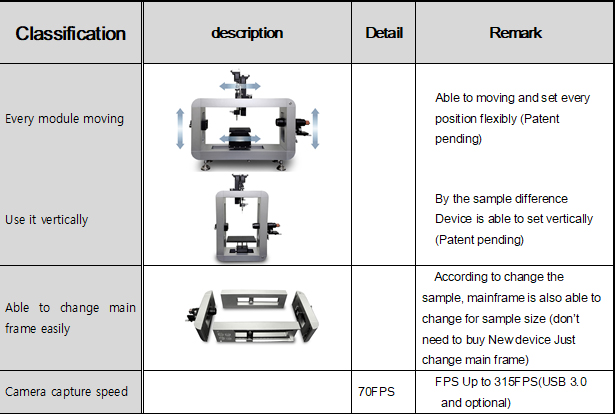

- Every main frame is able to change the length for its sample figure

New Stage Features 2:

New Stage Features 3:

Features

- Total flexibility: Easy to upgrade ( Manual → Auto One Drop → Multi syringes ) by modular design main frame.

- Automation : Automatic measurement progress at once

- User friendly : Easy to transform for changed sample types

- Tool Free changeover: Additional tools are not required for modular change.

- Changeable module position : According to sample nature, module can be change to cater for diverse sample nature/ form factor

- Huge application advantage :

Thin sample : Use on Horizontal platform

Bulky sample: move all modules ( camera, light source, stage, head ) into vertical position

- Data output : Data can be exported as Excel file, offering the highest flexibility for further data processing

Capabilities

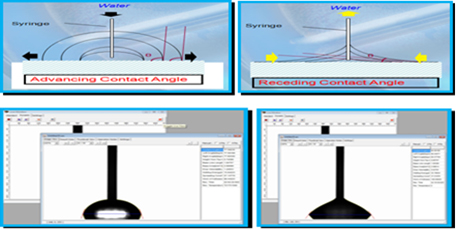

- Static / dynamic contact angle ( captive method & tilting method )

- Surface energy calculation

- Surface tension and interfacial tension by Pendent drop method

- Curve sample surface contact angle measurement

- One click operation – All process from dispense one drop of test liquid, touch drop of the liquid to sample surface with just one click.

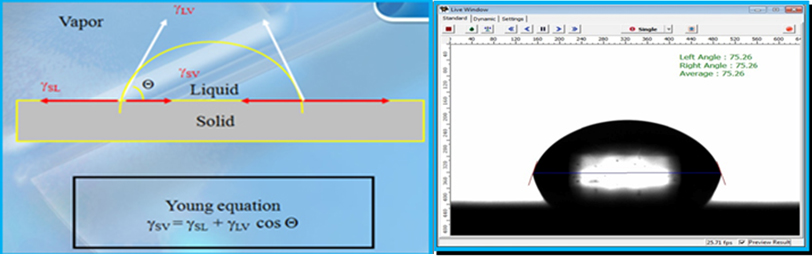

1.Static Contact angle measurement

Measurement range : 0~180°

2. Captive dynamic contact angle (Applied only Smart -A, Smart-T, model only)

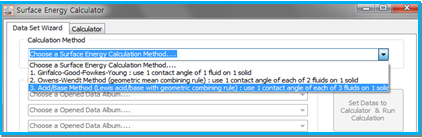

3. Easy Surface Energy calculator (GGFY, Owens Wendt, Lewis method)

Using measured contact angle data itself

4. Surface tension by pendent drop method

(1mN/m ~ 1000nM/m)

5. Curved surface sample measuring function

6. Automatic capture at after thermodynamic Equilibrium

(Applied only “Smart -T” model)

Able to get contact angle data from three phases thermodynamic equilibrium

Software function

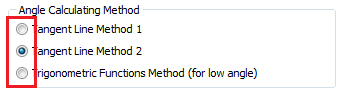

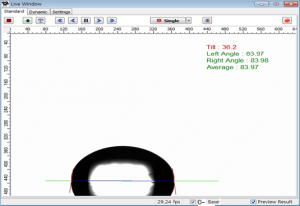

1. Static contact angle calculation by three modes

- Tangent line method 1(For Tilting contact angle and bigger drop volume)

- Tangent line method 2(For common measurement)

- Trigonometric function (For low angle measurement : less than 30degree)

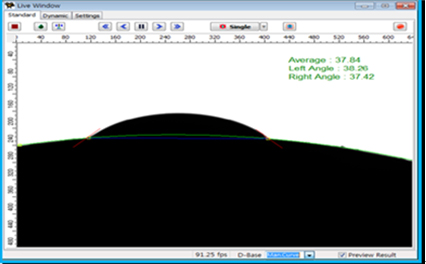

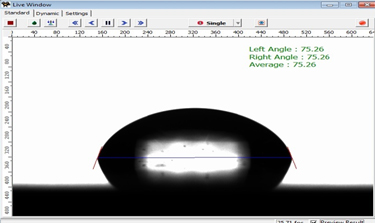

2. Realtime Preview Result before capture function

- Able to check condition of image before capture - Measurement data will be display before capture

- Able to check an instant contact angle and surface tension data

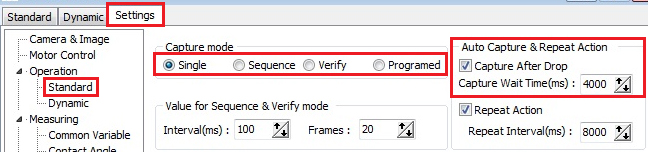

3. Automatic capture at after thermodynamic Equilibrium

Contact angle is based on three phases equilibrium, but it is dependent on Sample’s property. There is different equilibrium time for different sample. User is able to set equilibrium time as above.

4. Manual mode for critical sample

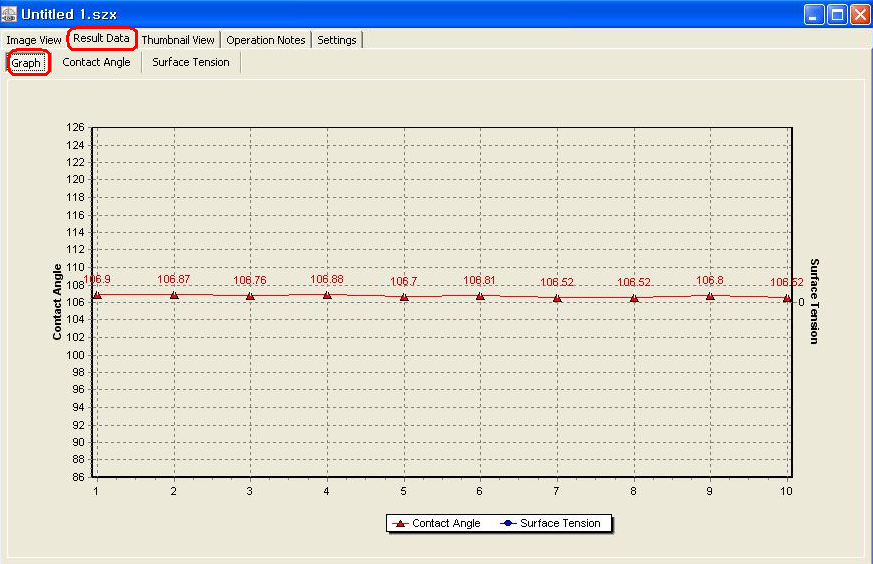

5. Auto calculate average

- Automatic calculation of the average contact angle data by the software based on the frames captured.

6. Graphical data

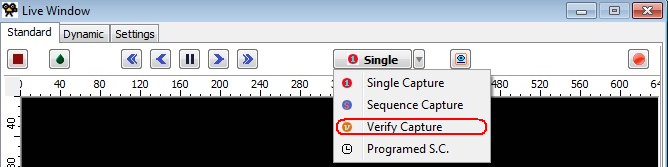

7. Four types of capture modes

7. Four types of capture modes

- Single mode - One by one capture image

- Sequence mode - Able to check by interval time base

- Verify mode - Will show only one Maximum frequent image

- Programmed mode - Use it with Tilting, Time base by triggering

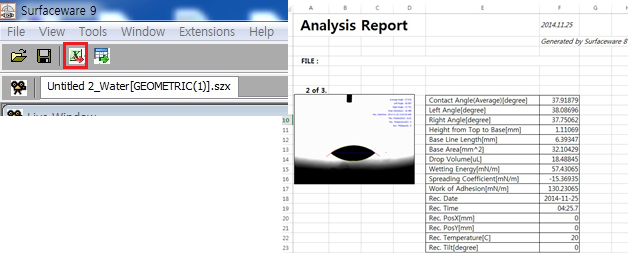

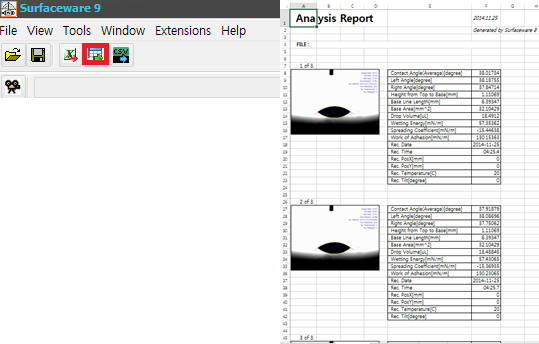

8. Export captured date to Excel (2 modes)

- Selected only one image export on whole measured image

- All images export at once into an collection

9. Manual define Base line function

- User can define the baseline manually for difficult to calculate contact angle

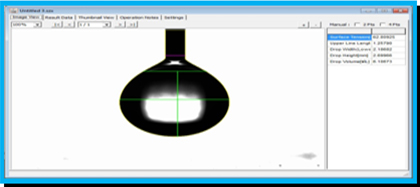

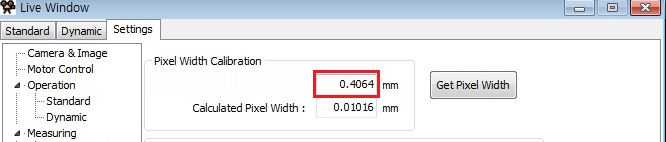

10. Precisely drop volume calculate

- Using SEO Pixel Width calibration, user can calculate the drop volume of the liquid precisely

Hardware Functions:

Data Analysis Specification

| Method and divided | Accuracy | Resolution | Range | Data information | Extension

(Remark) |

|

| Static contact angle | Tangent line metnod1 | ±0.1degree | ±0.01degree | 0~180° | Average contact angle, left contact angle, right contact angle, drop volume, height, base line length, base area, measured time, wetting energy, spreading coefficient, work of adhesion | |

| Tangent line metnod2 | ||||||

| Trigonometric function | ||||||

| Dynamic contact angle | Captive method | ±0.1degree | ±0.01degree | 1~180° | Advance angle, Receding angle, Hysterisis, drop volume, etc., | Applied model is only

P-MT (A,T) |

| Tilting method | ±0.1degree | ±0.01degree | 0~90° | Work of adhesion, Advance angle, Receding angle, Hysterisis, drop volume, etc., | (optional) | |

| Surface tension | Pendent drop method | ±0.1mN/m | ±0.01mN/m | 1~1000

mN/m |

Drop volume, Surface tension | |

| Surface free energy | G.G.F.Y | ±0.1mN/m | ±0.01mN/m | Surface free Energy | ||

| Owens-Wendt | ±0.1mN/m | ±0.01mN/m | Surface free Energy, Dispersive value and Polar value | |||

| Lewis (Acid/Base) | ±0.1mN/m | ±0.01mN/m | Surface free Energy, Dispersive, Polar, Acid, base value | |||

| Capture speed | CCD | 0~70FPS | Basic supplied is 70FPS | 0~315FPS (Optional) | ||

| Machine vision Resolution | 640x480 | Basic supplied is 640x480 | 1280x1024 (Optional) | |||

| System | Quantitative dispensing

with Head up-down automatically |

Applied only Phoenix—MT(T) model | ||||

| Dispensing by

3㎖syringe |

||||||

| Motor | Programmable drive

motor |

1/51200 | 1~51200 | Applied model

is only P-MT (A,T) |

||

| Data export method | Two modes of Excel export, BMP, CSV file | |||||

| Data save method | Save as .SZX

and Excel |

|||||

| Sample stage | X,Y axis sliding or Turning for wafer | Mapping(auto X,Y axis) is have to discuss with SEO) | ||||

| Device dimension | ||||||

| Device net weight | Depends on it | |||||

| Power | 110/220V(50/60HZ) |